Joh. Clouth was founded in 1874 in Remscheid, the “lakeside town on the mountain”. The company's history is chequered, but through two world wars it has always been linked to the paper and timber industry. It is therefore not surprising that saws and blades were originally made for a wide variety of industries, but also that doctor blades were already made of steel and bronze.

The Clouth Group - We are always developing new solutions

Since 1874, the name Clouth has stood for practised values such as quality, reliability, solution orientation and innovative force. These are the roots of the company, and also its future. Clouth products - doctor blades, coater blades, creping doctors, retainer systems and accessories - in use in every third paper machine around the world, and in every second machine in Europe.

Stations on our way

Success with Vulkollan

In later years, Clouth hit the big time with Vulkollan suction box linings: The coverings were extraordinarily wear-resistant and therefore only had to be renewed after 2 years, when the chemicals had destroyed the Vulkollan. The papermakers were highly satisfied with the runtime and Clouth was No. 1 in Europe.

A turning point in the 60s

In the mid-60s, however, the triumphant advance of plastic screens began, and this was also the immediate end of Vulkollan coatings, because the frictional resistance of plastic screen against Vulkollan was so high that the machines came to a standstill. What now?

Everything back to square one

Clouth would not be Clouth if they had now buried their heads in the sand. Thus, the company focused on producing essential wearing parts and high-quality capital goods for the paper industry: Doctor blades, coater blades, creping blades and even doctor holders. Since the production had to be rebuilt, there was a lot of manual work at the beginning. Holes were drilled manually and the rivets driven in with a hammer. Thus, there were only a few blade qualities: Steel, stainless steel, bronze and as “plastic doctor” PVC-Red, MG-FF-Trolitax and OG (Pertinax).

Standstill? Without us!

For a start, the company was well positioned and could equip the most common machines and batches. Problems arose when machine speeds increased. The stainless steel blades, tried and tested over decades, began to glow and spark. Acute fire hazard! Short-term improvement was brought by normal steel blades with higher hardness and greater carbon content. The disadvantage was higher abrasion on the granite rollers: The doctor blade life decreased and the grinding intervals for the rollers were reduced from 6 to 3 months.

He who laughs last …

In the mid-70s, Clouth brought out a doctor blade that can still be called a revolution today, because it is the “mother” of a whole generation of doctors. At first ridiculed by competitors from various countries, then copied with varying degrees of success: POLICLOUTH-SUPER®

This combination of glass fibre fabric with epoxy resin could be used practically from the breast roll to the pope reel, except for creping. Development continued and epoxy resin was combined with carborundum, carbon fibre, Kevlar, Teflon and aramid. In the meantime, there is a wide portfolio of doctor blades that have proven successful in the respective application.

Always one step ahead

The continued increase in machine speeds, the use of steam blow boxes and the end of granite as press rolls, forced and still forces doctor blade manufacturers to find ever new materials to meet the demands of modern paper machines.

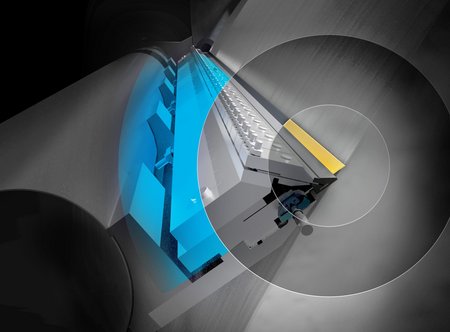

That is why Clouth set up its own production line for composite long-fibre boards in 2010. The largest and most modern in Europe at the time, capable of producing all the materials the market needs.

Innovations need space

For many years, it has been possible to combine production and innovation at the site in Remscheid and to find solutions when things got tight. Not least because they shied away from a move that would represent a Herculean logistical task. Another premise was that there must be no loss of production. But this challenge was also successfully mastered!

From Hückeswagen and into the world

Anyone who visits the head office of Joh. Clouth GmbH in Hückeswagen, you can't tell by looking at it that it has a long and sometimes chequered history. Because an initial glance around the site reveals that innovations are driven forwards here. A contemporary building, state-of-the-art production and communication technology, spacious production halls and well-organised processes dominate the scene. Clouth produces its own electricity and heat for production using a combined heat and power plant, and the vertical range of manufacture has been continuously increased significantly.

Today, over a century of experience is employed in order to specifically supply customers around the globe with serial and custom solutions. The products and services are currently available in over 70 countries around the world - this is ensured by a network of over 50 commercial representatives. Clouth competence is in demand everywhere - with steady growth and increasing potential.

Strong in cooperation

In addition to the headquarters in Hückeswagen, the Clouth Group has included Clouth Sprenger GmbH in Moers since 2003 and since 2006 Joh. Clouth GmbH - Eltmann site. Each location is dedicated to specialised tasks, but with a common goal: to always give the best for the customer.

Refined doctors from Clouth Sprenger - making good things even better

What began back in 2003, by sealing a joint venture agreement with a pragmatic handshake, is today a 20-year success story.

How it all began

The managing directors of Horst Sprenger GmbH in Moers and Joh. Clouth GmbH in Hückeswagen decided back then to consolidate the expertise of their teams in a joint company to produce coated doctor blades and coater blades for the paper industry. Customers enjoy a twofold advantage here: On the one hand the longer service lives of the products maximise their productivity, whilst the paper quality is also sustainably enhanced.

Horst Sprenger is a specialist in coater blade metering systems and Joh. Clouth is the world market leader in doctor blades. And so it was that Clouth Sprenger GmbH, based in Moers, was born.

The aim was to become a reliable supplier of coated creping blades and coater blades for our partners in the paper industry.

The initial staff of three was limited in size. The company moved into a 700 m2 hall on the site of Horst Sprenger GmbH and invested in the early machines; a first production line was established, initially for aluminium oxide-titanium oxide coated doctors and blades. Brimming with confidence and certainty that the product could be sold successfully as long as it was of the right quality.

But what may sound like a straightforward undertaking today demanded a challenging "trial and error" phase back then. The technology had further developed and the competition was initially well ahead, while there was also a lack of experience in grinding itself. The grinding wheels, which are crucial for the final product quality, initially lasted only 5 metres and were then worn out. It goes without saying that the ratio of saleable products to rejects was not favourable.

Always optimally networked

At this point, however, what was to become key to Clouth Sprenger GmbH's success going forward became clearly apparent: the will to succeed, the perseverance and inventiveness of the entire team, as well as a solid connection to the region. A small manufacturer of grinding wheels was in operation in Remscheid, where Joh. Clouth was based before relocating to Hückeswagen. Inspired by the idea and in support of the project, grinding wheels that met the requirements were now available in a record time of 24 hours. Thanks to the tireless efforts of the entire team with initially limited resources, we took a giant leap forwards with our development within a period of just 3 months.

From that point on, our company grew continuously. New colleagues joined us - from the application technology team, which develops the optimally adapted product for our customers, to the employees in research and quality assurance, to a dedicated administration team.

Sometimes things turn out differently - but equally successful

Although we had originally only targeted the coater blade market, we succeeded in establishing ourselves around the world in the field of coated creping doctors in particular, and we now supply one third of Europe's market. The company grew as more employees came to work at the site - all of whom demonstrated the same desire to move the company forward and to constantly improve production and product quality.

In addition to CERADIA® creping blades, which are perfectly adapted to the customer's process, Clouth Sprenger also focuses on the optimal performance of the creping blade bar. As such, in addition to our V-Guard - the online vibration monitoring system, we also offer the low-vibration Galeno creping system. Both are proprietary developments from Clouth Sprenger.

Our Clouth Sprenger team drives our customers' manufacturing processes forward with their usual reliability, know-how, commitment and our brand-leading CERADIA® quality.

Think tank for system solutions around the doctor blade in Eltmann

The company, which then traded under the name Elektro-Mechanische-Werkstätten-Eltmann GmbH (EMWE) was established by Helmut Strauch Dipl. Ing. (graduate in Engineering). As an experienced process engineer in a paper factory, he was well versed in the special needs and requirements of the industry. When he established the company, he had a clear vision: the development of special solutions and holder systems for the paper industry.

From prototype to series production - entry into easy-handling products around the doctor

Helmut Strauch already knew Klaus Kochenrath, the then managing director of Joh. Clouth GmbH. “Clouth”, as the company is known to this day was and still is a well known and established supplier to the paper industry – with a focus on doctor blades. And in the very first year of the establishment of the company in Eltmann, the first collaborative project was launched: Helmut Strauch developed the prototype of the Doctor-Pull. The doctor blade extractor was developed with a view to increasing safety by preventing accidents during blade changing and to simplifying the process as such.

Peter Kochenrath, who was already actively supporting his father in the company at that time, was immediately enthusiastic about the idea of this practical accessory. On receiving exclusive marketing rights, he presented the prototype to his customers. In part due to the active support of Joh. Clouth GmbH, the CLOUTH DOCTOR-PULL® is now one of the most popular accessories, especially in relation to occupational safety.

Spirit of innovation

In the following years, numerous new developments were designed, which – always supported by Clouth – were correspondingly optimised to meet customer needs: Prototypes were tested, modified and tested yet again until they reached the series production stage and provided the customers with the professional, reliable quality, which they had come to expect from all the companies of the Clouth Group.

Success and growth

With the growing success, the workforce also grew, so that the company headquarters were relocated from the tranquil district of Dippach to the industrial area of Eltmann. Perhaps it was only a fortunate coincidence, but the new building was resplendent in yellow and blue – the corporate colour scheme of the Clouth headquarters in Hückeswagen.

The final breakthrough

In 2003, the final breakthrough was achieved with the development of the CLOUTH® HS-1. Until then, contour double hose holders had been used on paper machines: Although the centre rod of these holders could be pulled out completely, before the cover plate could be removed, the sealing lip with countless screws had to be loosened first. With the CLOUTH® HS-1, the function of the hose and the sealing function of the front lip were combined in a spring plate. It was therefore possible to not only dispense with one of the hoses but also with the front seal. Dispensing with these components meant that the holder could be offered at a lower price than conventional double hose holders – in addition, it was even smaller, which in turn meant greater compactness.

However, the most important product feature that ensured worldwide success is that only two screws have to be detached to replace the cover plate – a revolution in holder design. This trend-setting development was also intensively supported by Clouth, so it is little surprise that the CLOUTH® HS-1 has been exclusively marketed by the Clouth Group since 2004, consolidating its leading role in the supplier industry.

The ideal complement

The long-lasting collaboration based on mutual trust culminated in 2006 when Clouth took over EMWE as part of a succession plan. Over time, this was followed by complete integration into the group of companies and ultimately, in 2023, the merger with the headquarters in Hückeswagen. The goal remained the development of individual system solutions for all customers who could not get anywhere with the standard. The focus lies on the production of special machines, custom units and investment goods, in particular doctor designs for the paper and sheet processing industry.

Tradition and modern

With all the modernity conveyed by the Clouth image, centrally there is a very clear connection with tradition and the resultant wealth of experience: The imposing granite roller directly in front of the main entrance is firmly and permanently anchored to the ground, due to its dimensions and weight. It was once delivered on a heavy goods transporter as a gift from the paper industry, and stand for the size and power of the Clouth name today.

The philosophy of Clouth Group

In addition to the wide range of solutions, our service is an elementary part of the portfolio and tailored to the dimensions of each customer. This way, they profit from the pronounced specialist expertise consolidated within Clouth, and are never alone in facing their challenges. We always focus on ensuring that our products can be utilised in the best possible way, and that their full quality comes to bear in application.

Thus positioned, we are well equipped for today's ecological and economic challenges, because environmental and climate protection is increasingly playing a key role in the paper industry in particular, and therefore also at Clouth. The longer service lives of wearing parts and the utilisation of savings potentials with raw and operating materials reduce the environmental impact of an entire sector.

The success story continues

The Clouth Group companies have been part of the Kadant family since June 2021.

Kadant is a global supplier of high quality engineered systems used in the process industry worldwide. Kadant is headquartered in Westford, Massachusetts, and employs approximately 2,600 people in 20 countries worldwide. Kadant's relentless focus on serving customers with high-performance products and service aligns with our business approach and is positioning Clouth well for continued growth. There was no question that the Clouth Group would remain as an independent brand, even competing with other companies in the Kadant family.

Stepping resolutely into the future with loyalty to tradition

Over the course of time, the Clouth Group has always taken on new challenges and has continuously and dynamically developed - with ambitious but clear goals in mind. Our know-how in the design of advanced materials, perfectly adapted to the respective requirements of doctoring or surface finishing, complements our view for solution development around the doctor/blade.

We want to continue to prove ourselves to our partners as a globally leading and reliable system partner for the doctoring and perfecting of surfaces.